Manufactured stone provides the realism of natural stone at an installed cost of a fraction of natural stone. Because Dutch Quality manufactured stone is made of lightweight material, it is classified as an adhered veneer as does not require a footing or mechanical support for installation.

Resources

Ours is a tradition of craftsmanship. And we have the info to prove it. From products to installation to care, get it here.

Downloads

-

Download

Download

2024 Brochure

-

View

View

Stone Visualizer

-

Download

Download

NCMA Installation Guide

-

View

View

NCMA Installation Guide - Spanish

-

View

View

NCMA Certified Installer Program

-

View

View

Find a Certified Installer

-

Download

Download

AIA CEU Course Offerings

-

Download

Download

Supplemental Install Guide

-

Download

Download

Supplemental Install Guide [Spanish]

-

View

View

3 Part Spec

-

Download

Download

Applications Over Continuous Insulation

-

Download

Download

Care & Maintenance

-

View

View

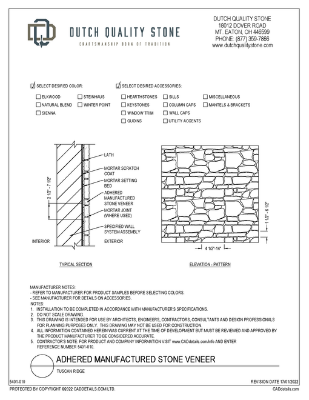

BIM + CAD Files

-

Download

Download

CAD Drawings

-

Download

Download

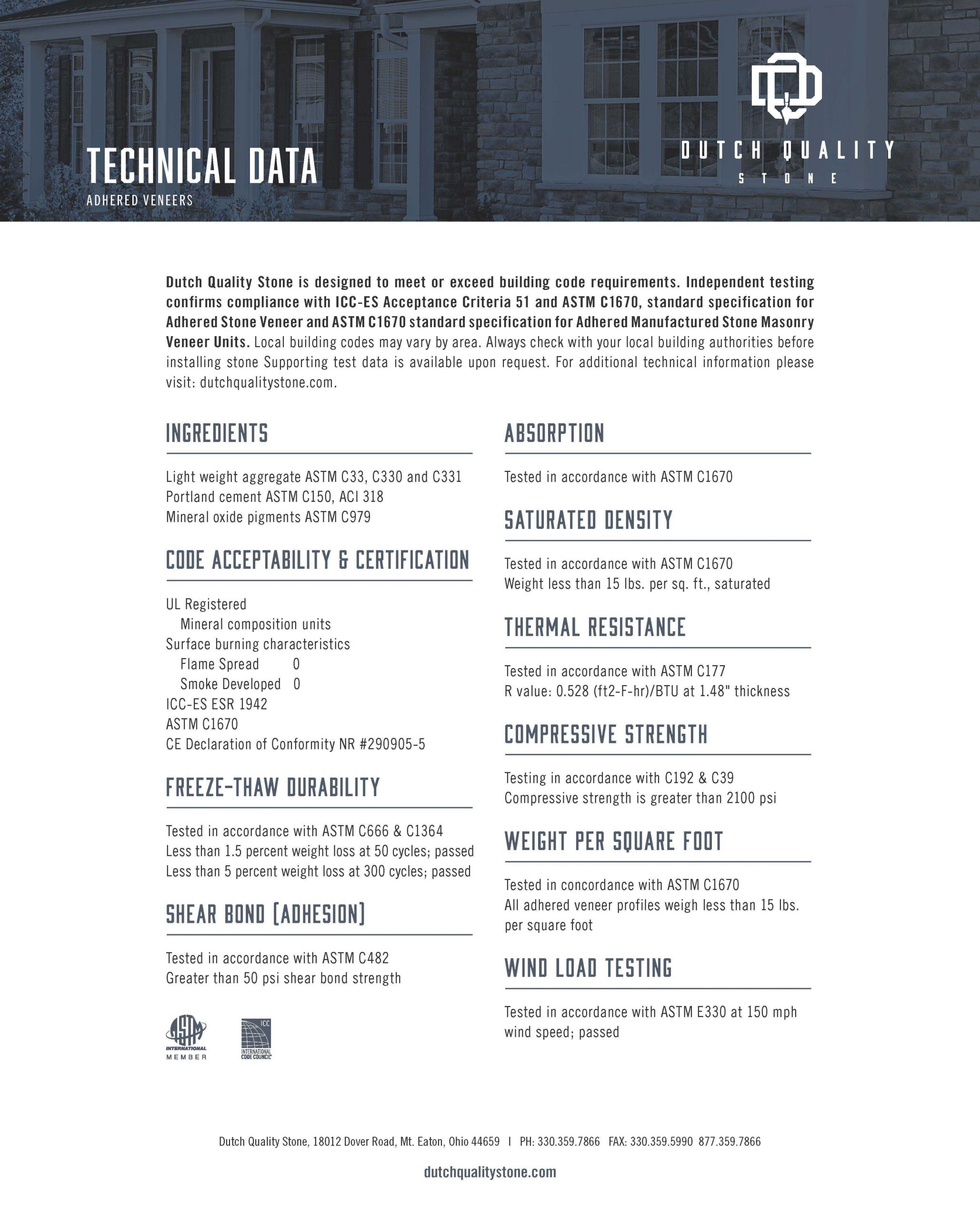

Technical Data Sheet

-

Download

Download

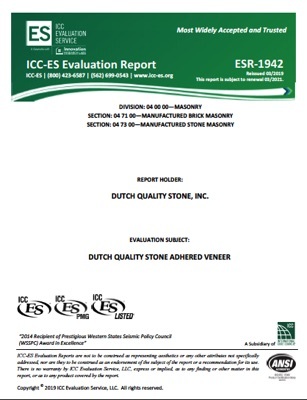

ICC Report

-

Download

Download

Safety Data Sheet (SDS)

-

Download

Download

Warranty

-

Download

Download

Architectural Binder

-

View

View

Technical Submittal Packet

-

Download

Download

Large Format Stone Installation

-

Download

Download

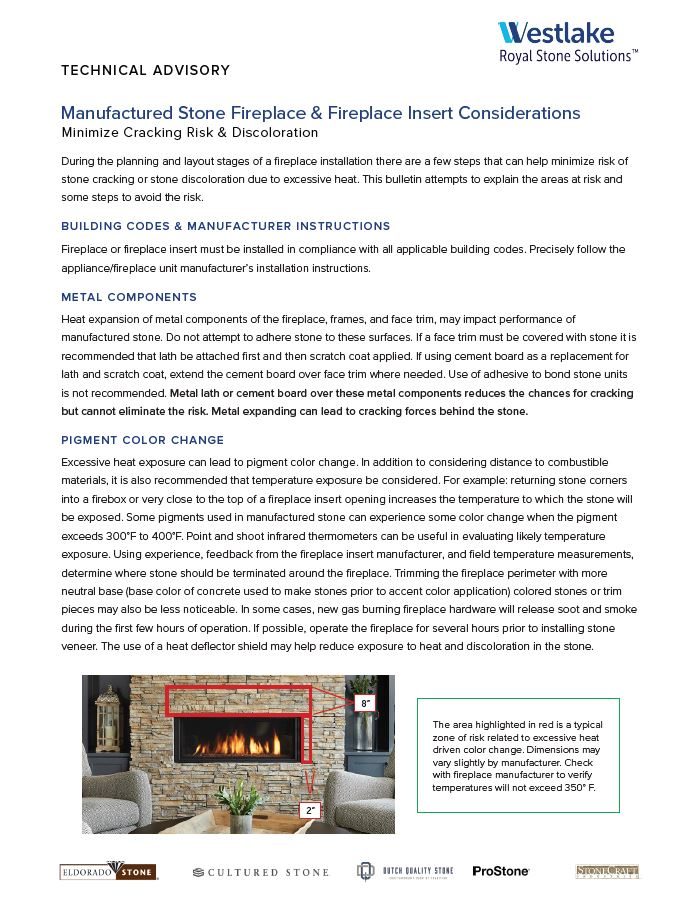

Technical Advisory: Using MSV on Fireplaces

-

Download

Download

Invite the Outdoors In

-

Download

Download

It's All About Curb Appeal

-

Download

Download

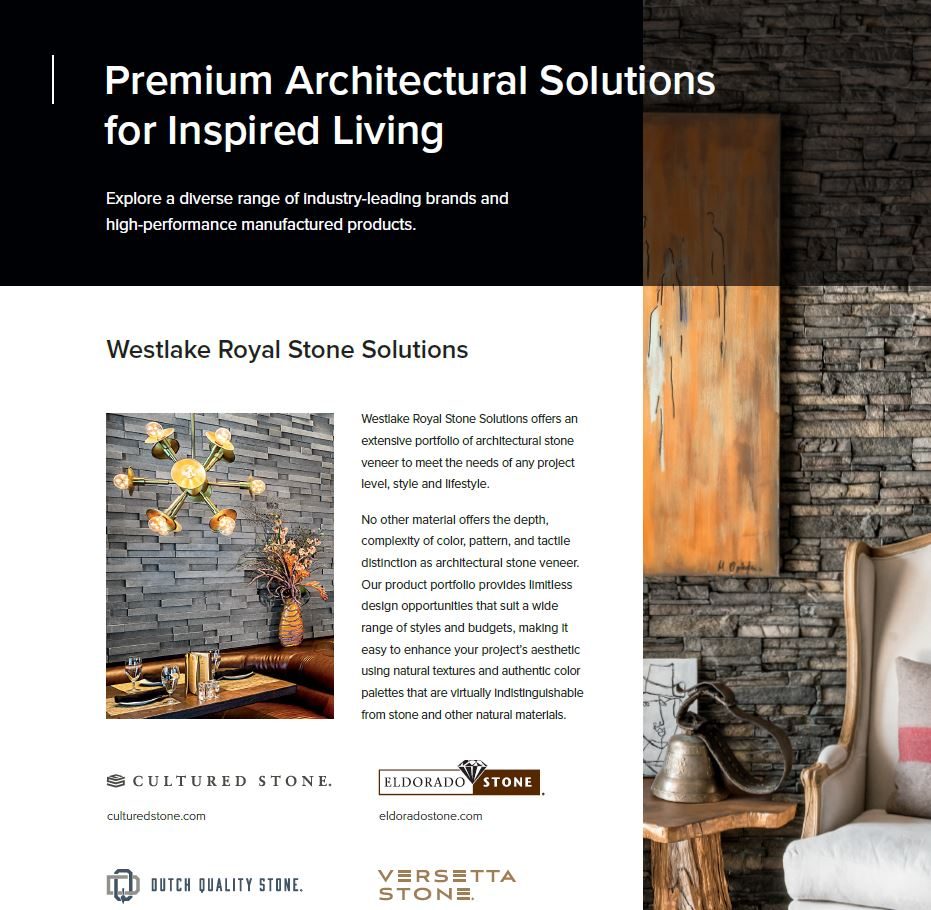

Architectural Solutions - Inspired Living

-

Download

Download

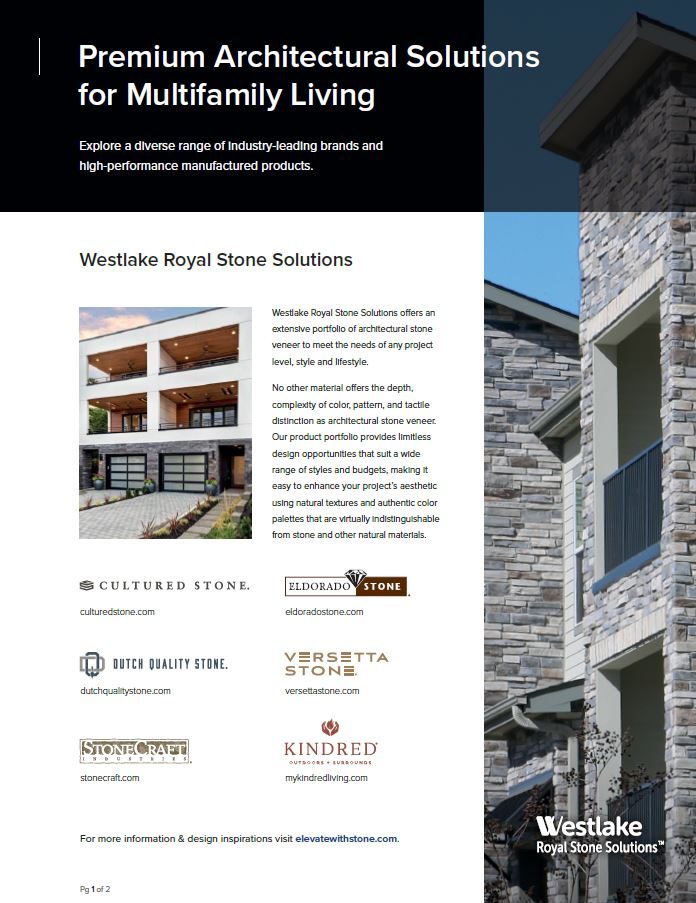

Architectural Solutions - Multifamily

-

Download

Download

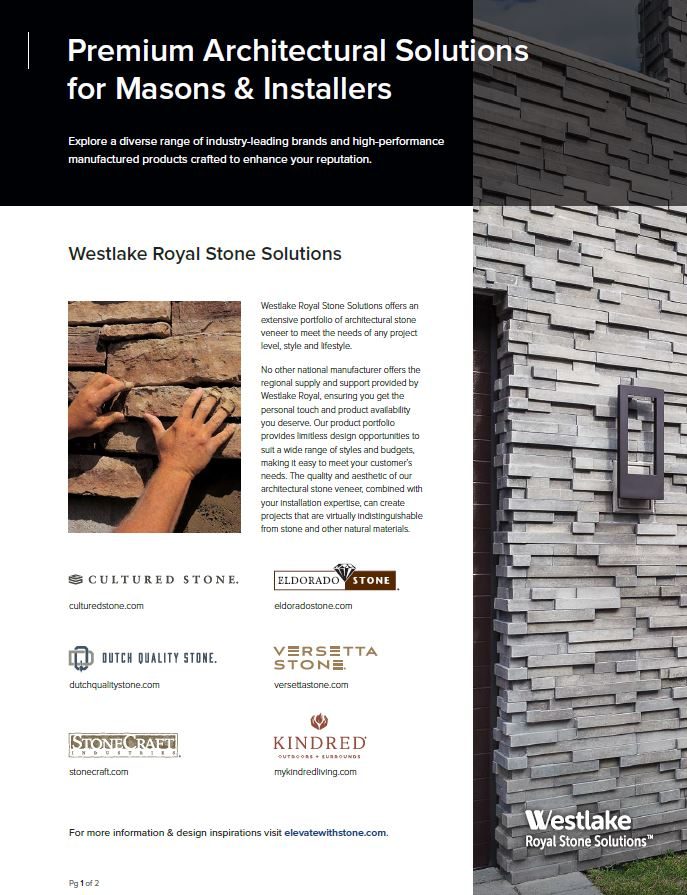

Architectural Solutions - Masons & Installers

-

Download

Download

Multifamily Brochure

-

Download

Download

Commercial Brochure

-

Download

Download

Residential Brochure

Frequently Asked Questions

Yes, for exterior applications use only cement board that complies with ASTM C1325. For interior installations, any ½” or 5/8″ cement board product is acceptable. Always bond the stone with polymer modified mortar compliant with ANSI A118.4 or ANSI A118.15. Do not use conventional Type S mortar for bonding Dutch Quality Stone to cement board.

Adhered stone veneer is designed and intended as a wall covering. Using adhered stone veneer on a horizontally oriented fashion is not preferred. Do not use adhered stone veneer as a paver or a wall cap. Do not install adhered stone in a situation in which continuous or frequent exposure to water is possible such as pool or Jacuzzi copings or surrounds. Adhered stone veneer is not intended to be installed on stair risers where deicing salts or snow shovels can damage the stone façade.

Type S mortar complying with ASTM C270 is the most common mortar used to bond adhered stone veneer. For additional strength in challenging conditions, use polymer modified mortars. The polymer modified mortars provide a superior bond that exceeds the minimum bond strength by a factor of 5x or greater. Polymer modified mortars also allow for stone movement during installation without losing bond strength, making it a great choice for tight dry-stacked stone profiles.

Note, always back butter the entire surface of the stone back. The thickness of the mortar should average about ½” when the stone is pressed into place on the wall.

Applying a sealer or coating that is not capable of “breathing” will jeopardize the long-term health of the wall structure. Moisture that can collect in the wall system must be able to dry out through the wall covering. However, the application of a silane or siloxane water repellent is recommended to prevent water absorption into the stone while rendering the color, texture and breathability of the stone veneer unaffected. For the health and safety of the application, select a water-based (rather than a solvent-based) silane or siloxane repellent. These products can be brushed, rolled or sprayed on the stone veneer.

The building code requires a clearance between the stone veneer and the grade or ground level. There are several reasons for this and most of these reasons involve protection of the wall, not the stone! Behind the stone veneer is a drainage plane that was created when the weather-resistive barrier was installed. The purpose of this plane is to collect and direct any water that squeaks behind the wall façade downward and out the base of the wall. If the base of the veneer wall is at or below grade, proper drainage will be impaired. Secondly, water that pools or collects at the wall base can rise into the wall through capillary action and enter the structure. Thirdly, if the veneer is in contact with vegetation (grass, plants, etc.), growth into the wall is possible. Also, bugs and insects, including termites, will find it convenient to enter the wall system when the wall is in direct contact with earth. Finally, the stone is not designed to be continually wet or subject to the harsh chemicals found in soils.

50-year transferable warranty

Dutch Quality Stone stands behind all of our products, and they are offered with a limited warranty.